Description

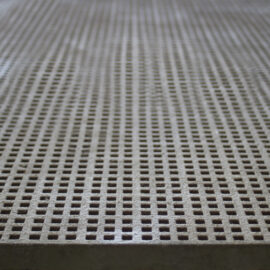

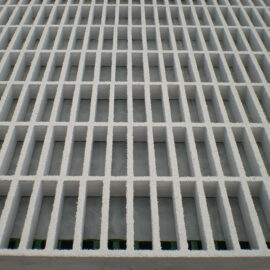

Phenolic grating offers maximum fire resistance, low smoke and low toxic fume emissions and low char yield making it the number one choice in sites at high risk of fire or in enclosed spaces such as tunnels where fumes can build up. Non-flammability enables it to withstand direct flame for an extended period without sustaining major structural damage. It’s most commonly used for high risk working areas such as oil rigs, underground tunnels, subways, refineries, ship decks and ship lifeboat access gangways.

Phenolic Grating has 12 to 14 week lead time.

If you would like us to quote or need more information, contact us here.

Other types of grating we offer includes Concave, Conductive and Vinyl Ester.